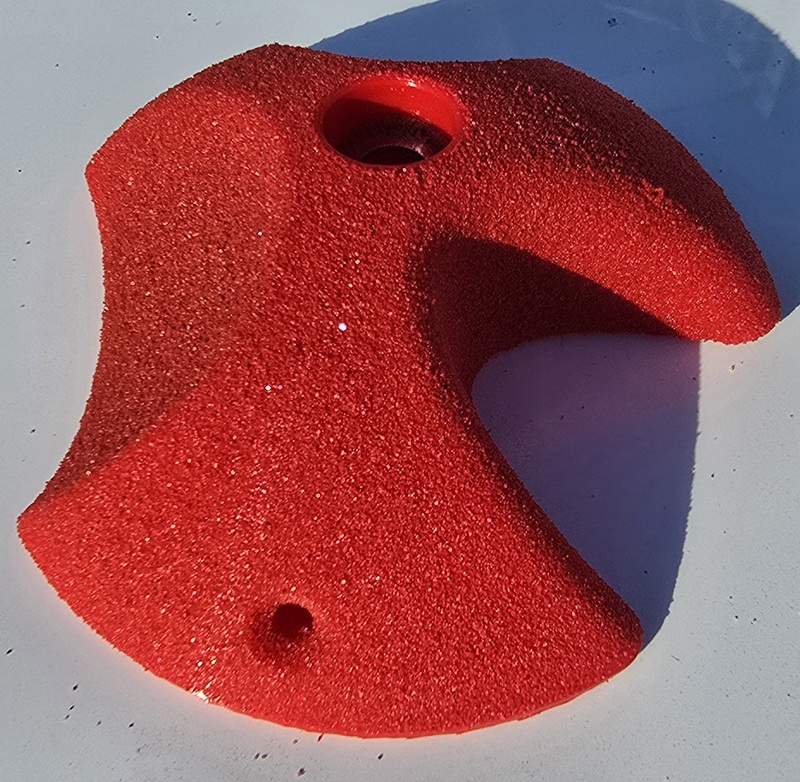

Self-Cast 3D Printed Climbing Holds.

Where the mold is the hold and the hold is the mold!

80% cheaper and win the 'Pepsi Challenge' on texture.

Download design

Print it

Cast It

Add Texture

Climb it!

We've made making your own holds as easy as pie, for peanuts...

Until now the only way to make your own holds was to carve in foam, make a mould and then cast. Or carve and sand wood.

But for your home woody, why go to all the effort and expense of making moulds when you don't want dozens of the same hold?

And sure working with wood is fun, but carving a hundred wooden grips will send you crazy!

We have the solution: Self-cast 3D printed holds, or 'mholds'. The hold is the mold and the mold is the hold!

%

% cheaper

%

effort

%

as STRONG & TEXTURED

★★★★★

“There are companies centered in customer experience, and then there is 5 Tendons. The focus they've put into doing some solid, legit, intricate-shaped hold.. it's impressive. From climber to climber, great surface, creative shapes, safe system and great price. Very recommended!"

Michelle C.

Climber and Engineer

Why Choose 5 tendons holds?

It's a simple customisable system to produce lots of holds for the lowest cost possible, with no compromise on texture and design.

It's easy

Each step is very straight forward. We've taken the head-ache of hold design out of the equation for you. Our Founder and Head Designer Brad Jeffery has 40 years of climbing and wall building experience and puts that experience into every design. Just browse our models and purchase what you like as you need new holds. Print them, mix up some Polyester resin with sand and pour. You can add surface texture before or after casting. Each week you will output dozens of holds for so cheap you'll just make more. It's a very satisfying end result. Don't have a 3D printer? Well you'll save so much you'll be able to buy one and then have holds on tap.

Customisable

You get different sizes and some with edge size/angle derivitives. You also get files with cut-outs to create dual-texture holds. Paint 'fuzzy skin' on certain sections during printing for a different dual-texture feel. Mirror holds to maximise variety. Some appropriate hold files come with a bolt hole plug to hide the hole. You can have holds which look identical from below but are unknown until the climber grabs them. If a hold is too easy for a route you're setting, just print the next harder variant of that hold and give it a go. Or the opposite, if the hold is too hard print an easier version. Or change where the texture is applied. Route set with true creativity!

Strength and durability

3D printed parts suffer from layer separation and is why printed climbing holds haven't really taken off. Even at 100% infill, catastrophic failure is still a possibility under high perpendicular loads. We've worked around this problem by creating a thin walled (2.4mm) shell which is then filled with resin. The resin bonds to the wall which makes the hold extremely strong. An integrated washer seat and print-in-place bolt protecting shaft rounds off a simple yet very cost effective way to make strong, reliable holds of any size.

FAQs

Are the holds strong

The holds are as strong as regular holds. They are essentially a hold with a plastic skin. So in fact they are a bit stronger as the skin acts as a shock absorber if dropped or struck. The skin bonds extremely well to the resin ensuring longevity of your holds.

How much are each hold?

They are available in packs: 60 designs for $49 and a lifetime subscription for $99 AUD

How much and what type of filament does each hold use?

Our medium sized holds use about 50-60 grams of PETG filament. We only use PETG for maximum versatility, as this material is hardy, compatible with Polyester resin and has good UV properties. Currently you can get PETG for about 14 USD per 1000 grams, that's 1.4 cents per gram. So an average medium sized hold will cost 70 to 84 cents USD to print (not including electricity). Note: Only use PETG!

How much resin is needed for an average medium sized hole?

The average medium sized hold has a volume of between 100 and 200mls. With a mix of 70/30 resin to sand mix, you'll need about 60-80 mls of Polyester resin per hold. 20 litres of (5.2 gallons) of Polyester resin sets you back about 140 USD, so a ml of resin costs about .007 cents USD. Therefore an average medium sized hold will cost at max 70 cents USD to fill even without sand. Pretty cheap hey! You can also throw in scrap plastic to fill out the volume. Finally somehere to dispose of all that scrap plastic from printing....

What about surface texture?

Many features in gyms are coated for surface texture. Our grips are no different. There are a few techniques to use for finishing off your grips. You can drizzle, paint or roller with a resin/sand mix. Or for the best texture, use Aluminium Oxide 150-180 grit seived onto clear acrylic spray paint. You can easily create dual texture grips. You will unleash your creativy finishing your grips! You can read more about texturing climbing holds on our how-to page here.

60 Hold Pack

Dip your toe in- An editors pick of 60+ of our holds, many with variants. 169 individual holds!

- 5% discount off Signature Lines.

- Upgrade pro-rata to Lifetime Subscription at any time.

Lifetime Membership

Most value- Lifetime access to all our designs (currently 100+ designs, 200+ unique holds). Exludes Signature Lines

- New holds every week!

- 25% discount off Signature Lines from top climbers and route setters

- Priority Support

- Access to our Reseller Program